All these components often need to be fitted in close proximity to capacitors the size of a can of Coke. Power inverters have bulky electrolytic capacitors, PFC coils that dissipate considerable amounts of power, and power modules whose pins barely allow you to meet isolation requirements. The feature has been an absolute life-saver on multiple occasions when working in the power inverter industry. Altium Mcad Co-designer running inside of Solidworks.

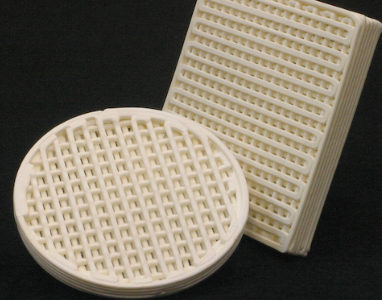

The 3D-first approach has always been one of the platform strongpoints and is one of the many reasons I always ended picking Altium Designer as my go-to ECAD software. Altium Designer offers a fully integrated environment where 2D and 3D go hand-in-hand, and you can do 2D layout functions in the 3D MCAD view in Altium Designer. Most ECAD software has always integrated some sort of 3D export, but in my personal view, the features were often half-hearted attempts meant at most to check if the board fit the enclosure. Thanks to the project hosting features through Altium 365, it's easy to open a shared project in Altium Designer and import it into one of these popular MCAD applications.Īltium Designer® was the first software in the ECAD industry to embrace 3D seriously. One of Altium 365’s best features is the support for mechanical collaboration with SolidWorks, PTC Creo and Autodesk Inventor. I’ve been enjoying working with Altium Concord Pro® hosted on the Altium 365® cloud recently. There may be issues with them, make sure you check before committing to a print.Altium Concord Pro™ as a standalone product and brand name has been discontinued and the capabilities are now available as part of our Altium enterprise solutions. The files above are what I used, but that doesn’t mean I did them right. Test tile with example textures at 100% sizeĭisclaimer: I’m pretty new to 3D modelling and had never used Blender before this project. I intend to make a second mould with a different texture, but the overall mould block will stay the same.īasic test tile (smooth sided) at 100% size The mould is designed to tesselate with itself, so two prints of the same design make up both sides. I went with 112% for the mould, but scale according to your slip. The amount you’ll have to allow for shrinkage will vary with different clays. In this case, 100% was intended to be the bisque size for dipping. So, all that said, here are the relevant STL files. They are neat enough to keep as ornaments I can have multiple textures per tile without any additional effort (eg, the Impulse dots) I can fully dip the tile in 30ml of glaze (around half that of my thrown tiles) Plus there are a few advantages to these test tiles: Yes, this is totally overkill for a test tile, but it’s also a perfect item to learn the process on.

0 kommentar(er)

0 kommentar(er)